Stay in touch with the latest Kingspan News here:

News & Insights | Kingspan Group

Kingspan Group LinkedIn

Copyright © 2025 Kingspan®, All rights reserved.

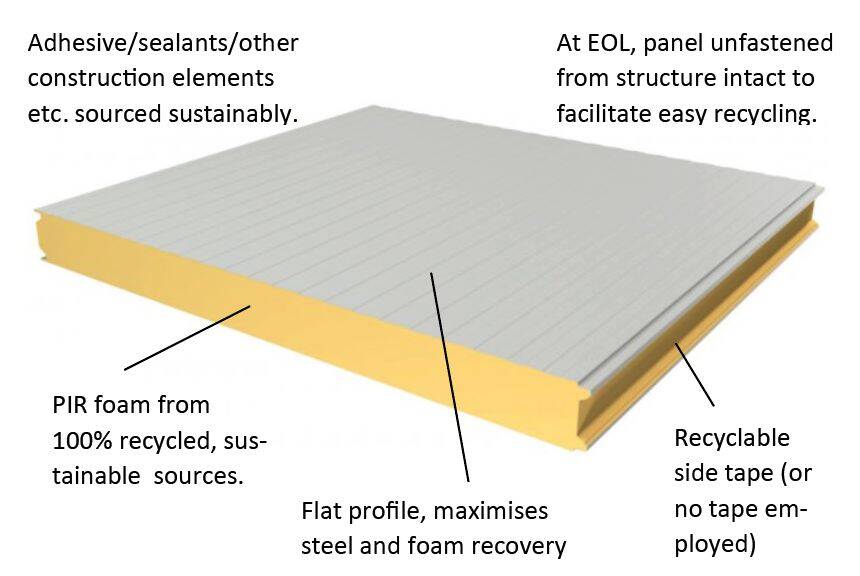

End-to-end circular panel process considerations.

We are now keen to get the input of interested colleagues across the divisions, to ensure the design is relevant and achievable.

A suggested improvement is the development of a circular side-tape solution to eliminate the present non-circular PE/PP material – is there a recyclable or bio-based solution?

There is positive sentiment towards flatter designs

(see figure on right) to facilitate recovery – but is this the best approach?

The idea of flattened roofing designs to allow easier stacking and transport after dismantling is popular, but does this impact performance in other areas?

Is the trade-off worth it or is there a better option?

Project background:

Kingspan’s involvement in the Circular Foam project is to develop and consider all aspects relating to circular insulated panels; including circular design, incorporation of recycled precursors, application of digital technologies, stakeholder engagement, sorting and recycling, and the above technology demonstrator.

INNOVATION

Resource links:

Circular Foam

website

Kingspan’s Customer

experience report

Kingspan’s Circular prototype panel preliminary report

Please Note:

Foam chemistry isn’t covered in this aspect of the project.

Any promising, IP-sensitive suggestions made will potentially be developed through a separate, internal project.

The final design will be fabricated on the IKON pilot press and employed in a small exemplar, in the summer of 2025.

If you wish to contribute ideas or simply want more details, please feel free to contact Karl at IKON karl.crowley@kingspan.com

If you are interested in contributing to the development of circular Kingspan products, we’d love to hear your thoughts and ideas. We are currently encouraging any interested colleagues to share their panel design ideas, as the IKON team work to develop a circular panel design, as part of the EU Horizon 2020 Circular Foam project.

Key areas we would be looking to improve would be:

The physical design of the panel – are there any design changes that could be made to improve circularity?

Changes to the steel, side-tape, fittings and fastenings to facilitate reuse/recycling.

Methods of installing and de-installing the panel to allow for efficient retro-fitting, re-use and ultimately recycling of the panel.

Ensuring that any of the above changes to design and process are safe, cost-effective and genuinely circular.

Our preliminary report summarised the main challenges of developing a prototype circular panel and customer feedback regarding circularity in construction (links below).

Help us create our first Circular Panel design

Copyright © 2025 Kingspan®, All rights reserved.

Circular Foam website

Kingspan’s Customer experience report

Kingspan’s Circular prototype panel preliminary report

Read the articles here:

Read the articles here:

End-to-end circular panel process considerations.

Stay in touch with the latest Kingspan News here:

News & Insights | Kingspan Group

Kingspan Group LinkedIn

Help us create our first Circular Panel design

Project background:

Kingspan’s involvement in the Circular Foam project is to develop and consider all aspects relating to circular insulated panels; including circular design, incorporation of recycled precursors, application of digital technologies, stakeholder engagement, sorting and recycling, and the above technology demonstrator.

Please Note:

Foam chemistry isn’t covered in this aspect of the project.

Any promising, IP-sensitive suggestions made will potentially be developed through a separate, internal project.

The final design will be fabricated on the IKON pilot press and employed in a small exemplar, in the summer of 2025.

If you wish to contribute ideas or simply want more details, please feel free to contact Karl at IKON karl.crowley@kingspan.com

If you are interested in contributing to the development of circular Kingspan products, we’d love to hear your thoughts and ideas. We are currently encouraging any interested colleagues to share their panel design ideas, as the IKON team work to develop a circular panel design, as part of the EU Horizon 2020 Circular Foam project.

Key areas we would be looking to improve

would be:

The physical design of the panel – are there any design changes that could be made to improve circularity?

Changes to the steel, side-tape, fittings and fastenings to facilitate reuse/recycling.

Methods of installing and de-installing the panel to allow for efficient retro-fitting, re-use and ultimately recycling of the panel.

Ensuring that any of the above changes to design and process are safe, cost-effective and genuinely circular.

Our preliminary report summarised the main challenges of developing a prototype circular panel and customer feedback regarding circularity in construction (links below).

We are now keen to get the input of interested colleagues across the divisions, to ensure the design is relevant and achievable.

A suggested improvement is the development of a circular side-tape solution to eliminate the present non-circular PE/PP material – is there a recyclable or bio-based solution?

There is positive sentiment towards flatter designs

(see figure on right) to facilitate recovery – but is this the best approach?

The idea of flattened roofing designs to allow easier stacking and transport after dismantling is popular, but does this impact performance in other areas?

Is the trade-off worth it or is there a better option?